Unparalleled Excellence in China Precision Mold Manufacturing: Transforming the Metal Fabrication Industry

In the rapidly evolving landscape of modern manufacturing, the role of precision molds cannot be overstated. As the backbone of countless industries, from automotive to electronics, the demand for high-quality, durable and cost-effective molds continues to surge. Among global players, China has established itself as a dominant force in china precision mold manufacturing, setting industry standards with innovative techniques, advanced technology, and a relentless pursuit of excellence. DeepMould.net exemplifies this trend, providing comprehensive solutions within the metal fabricators category that elevate the standards of precision engineering.

Understanding the Significance of China Precision Mold in Modern Manufacturing

The china precision mold industry is pivotal to the global supply chain, especially due to its focus on precision, efficiency, and affordability. Precision molds are intricately designed tools that shape raw materials like plastics, metals, or composites into final products with high exactness. They influence the quality, performance, and aesthetic appeal of finished goods, underscoring their importance in mass production settings.

China's rapidly advancing mold industry has garnered a reputation for combining innovative manufacturing processes with competitive pricing, ensuring quality does not come at the expense of affordability. This has led to increased exports, partnerships, and collaborations worldwide, positioning China as a top-choice destination for metal fabricators and companies seeking precision molding solutions.

Why China Precision Mold Works: Key Advantages for Global Industries

- Advanced Manufacturing Technologies: Chinese mold manufacturers employ state-of-the-art CNC machining, EDM, and laser engraving technologies that guarantee high precision and complex geometries.

- Cost-Effectiveness: The competitive labor costs combined with efficient manufacturing processes allow for high-quality molds at significantly lower prices than Western counterparts.

- Rapid Turnaround: Short lead times are achieved through streamlined workflows, localized supply chains, and dedicated R&D centers.

- Customization and Innovation: Chinese firms excel in crafting customized molds that meet specific client needs, supported by innovative design capabilities and R&D investments.

- Quality Assurance: Many manufacturers adhere to international standards such as ISO 9001, ensuring consistent quality and reliability across products.

DeepMould.net: A Benchmark in China Precision Mold Manufacturing

DeepMould.net stands out as a premier provider within the metal fabricators category, committed to delivering excellence in china precision mold solutions. Backed by cutting-edge technology, experienced engineers, and a customer-centric approach, DeepMould.net offers a comprehensive portfolio of mold design, manufacturing, and testing services tailored to diverse industrial applications.

From initial concept to mass production, DeepMould.net ensures every china precision mold produced meets stringent quality standards, providing clients with reliable tools that optimize efficiency and product quality.

Innovative Manufacturing Capabilities of DeepMould.net

The backbone of DeepMould.net’s success lies in its advanced capabilities, which include:

- Precision CNC Machining: Utilizes high-speed, multi-axis CNC machines capable of achieving micron-level accuracy.

- Wire and Die Sinking EDM: Ensures fine detail and complex shape creation necessary for intricate molds.

- Hardening and Surface Treatments: Processes such as nitriding, PVD coatings, and polishing enhance the mold's lifespan and performance.

- Rapid Prototyping and 3D Printing: Accelerates the design validation process, reducing time to market.

- Advanced Software Integration: Using CAD/CAM systems that allow for precise simulation and optimization of mold design before manufacturing.

Comprehensive Services Offered by DeepMould.net in China Precision Mold Manufacturing

DeepMould.net provides end-to-end solutions including:

- Mold Design and Engineering: Custom design services tailored to client specifications, ensuring manufacturability and cost efficiency.

- Prototype Development: Creating functional prototypes to validate design and functionality before mass production.

- High-Precision Manufacturing: Utilizing the latest machinery and techniques to produce molds with tight tolerances and complex features.

- Testing and Quality Control: Rigorous testing protocols to detect defects, measure tolerances, and verify performance.

- After-Sales Support and Maintenance: Ongoing support to ensure molds function optimally throughout their lifecycle.

Industries Benefitting from China Precision Mold Innovation

The versatility and reliability of china precision mold manufacturing solutions have fostered widespread adoption across multiple sectors:

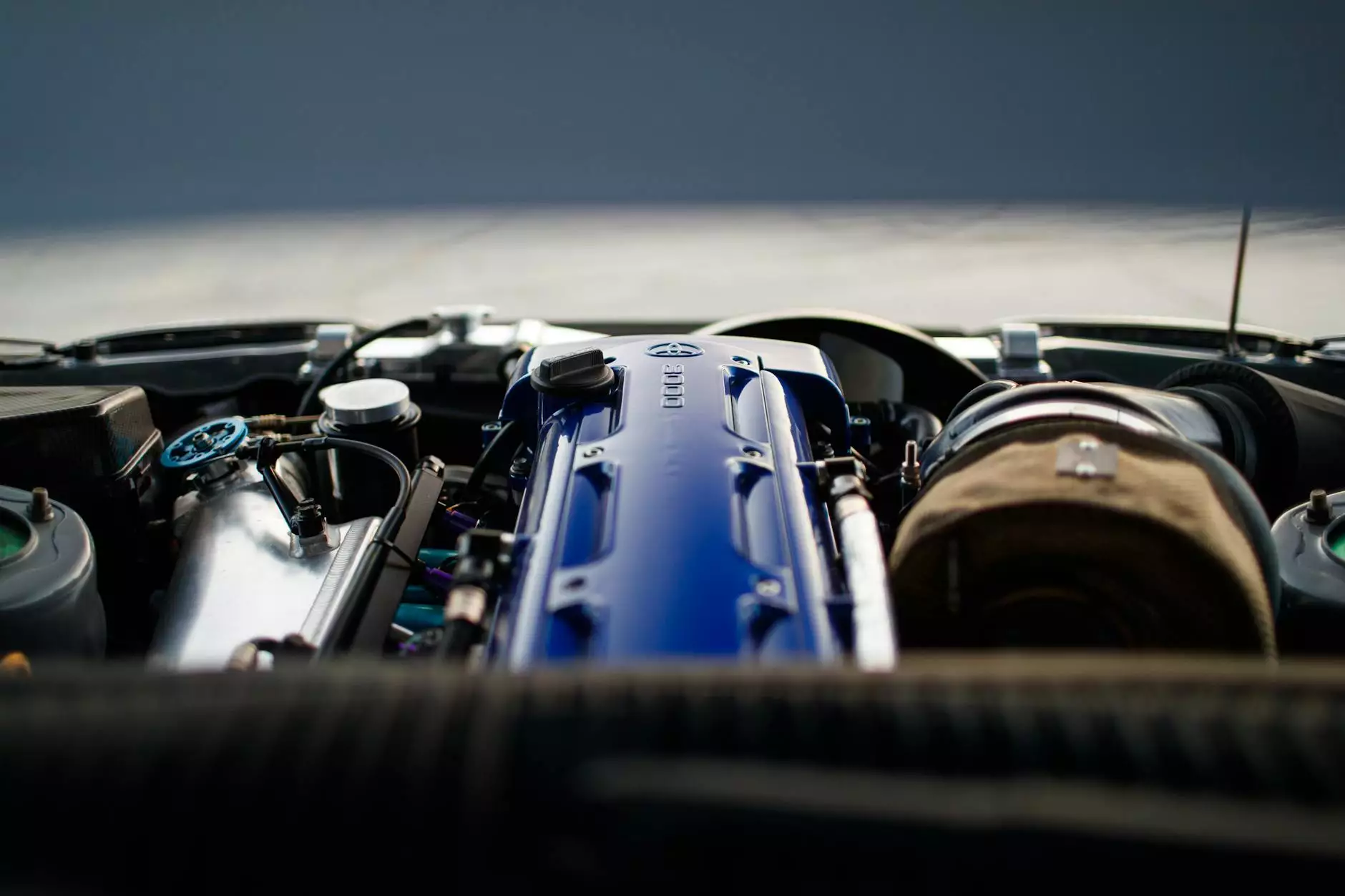

- Automotive: Production of complex automotive components such as dashboards, interior trims, and engine parts.

- Electronics: Precision molds for smartphone shells, circuit boards, and other electronic enclosures.

- Medical Devices: High-precision, hygienic molds for medical equipment, implant parts, and diagnostic devices.

- Consumer Goods: Molds for household appliances, toys, and fashion accessories that demand high quality and aesthetic appeal.

- Packaging: Injection molds for containers, caps, and closures with optimal durability and functionality.

Sustainable and Future-Ready China Mold Manufacturing

Modern Chinese mold manufacturers are increasingly committed to sustainability, adopting eco-friendly materials and energy-efficient production processes. Innovations in china precision mold manufacturing include the use of biodegradable lubricants, recyclable materials, and waste reduction strategies that align with global environmental standards.

Looking ahead, the industry is embracing automation, artificial intelligence, and Industry 4.0 principles to further enhance precision, productivity, and flexibility. Companies like DeepMould.net are investing heavily in R&D to stay ahead of technological trends, ensuring they provide innovative, sustainable, and future-proof solutions for their clients.

Choosing the Right Partner for Your China Precision Mold Needs

Partnering with a reputable china precision mold manufacturer requires careful consideration. Key factors to evaluate include:

- Technical Capabilities: Expertise in complex mold design, manufacturing, and testing procedures.

- Quality Assurance: Certification standards, quality control practices, and consistency of output.

- Lead Times: Ability to deliver within project timelines without compromising quality.

- Customer Support: Responsive communication and post-sales service to address potential issues.

- Cost Efficiency: Competitive pricing balanced with high standards of craftsmanship.

DeepMould.net exemplifies these qualities, making it an ideal choice for global businesses seeking reliable, innovative, and affordable china precision mold solutions.

Conclusion: Embracing the Future of Precision Molding with China Industry Leaders

The china precision mold industry continues to grow and innovate at an unprecedented pace, driven by technological advancements and increasing global demand. Companies like DeepMould.net are at the forefront of this transformation, delivering high-quality, customized solutions that empower industries worldwide.

Investing in superior china precision mold manufacturing not only enhances product quality and production efficiency but also provides a competitive edge in a crowded marketplace. As the industry evolves, embracing innovative technologies and sustainable practices will be essential for long-term success.

For businesses looking to optimize their manufacturing processes, partner with a trusted provider in China’s precision mold sector. Discover how DeepMould.net can support your needs with tailored solutions, cutting-edge technology, and unmatched expertise—unlocking new possibilities for your enterprise today.